Delve into the world of 3D printable computer cases, where style meets functionality. With endless customization options, these cases offer a unique solution for PC enthusiasts. Get ready to explore the exciting possibilities of 3D printing in the realm of computer hardware.

Introduction to 3D Printable Computer Cases

A 3D printable computer case is a computer case that can be created using a 3D printer. It is designed to house the components of a computer, such as the motherboard, graphics card, and storage devices, while providing protection and ventilation.

The purpose of a computer case is to keep the components organized, safe from external damage, and maintain efficient airflow to prevent overheating.

Benefits of Using a 3D Printable Computer Case

Using a 3D printable computer case offers several advantages:

- Customizability: One of the main benefits of 3D printable computer cases is the ability to customize the design according to individual preferences. Users can modify the case dimensions, add or remove features, and even create unique designs that suit their specific needs.

- Cost-effectiveness: Traditional computer cases can be expensive, especially if you are looking for unique designs or specialized features. With a 3D printable computer case, you have the option to create your own case at a lower cost, using readily available materials.

- Flexibility: 3D printable computer cases offer a high level of flexibility. You can easily make adjustments or modifications to the case design as your computer hardware requirements change over time. This flexibility allows for future upgrades and modifications without the need to purchase a new case.

If you need a printable 20 dollar bill, look no further! You can find one at this website . This printable is a great tool for teaching about money or for fun activities like playing pretend store. With this printable, you can familiarize yourself with the design of a 20 dollar bill and even practice counting and making change.

It’s a convenient resource that can be used in various educational settings or for creative play. So why not give it a try and print your own 20 dollar bill today?

- Eco-friendly: By utilizing 3D printable computer cases, you can reduce electronic waste. Instead of disposing of old cases when upgrading your computer, you can simply print a new case that fits the updated components. This promotes sustainability and minimizes the impact on the environment.

Examples of Popular 3D Printable Computer Case Designs

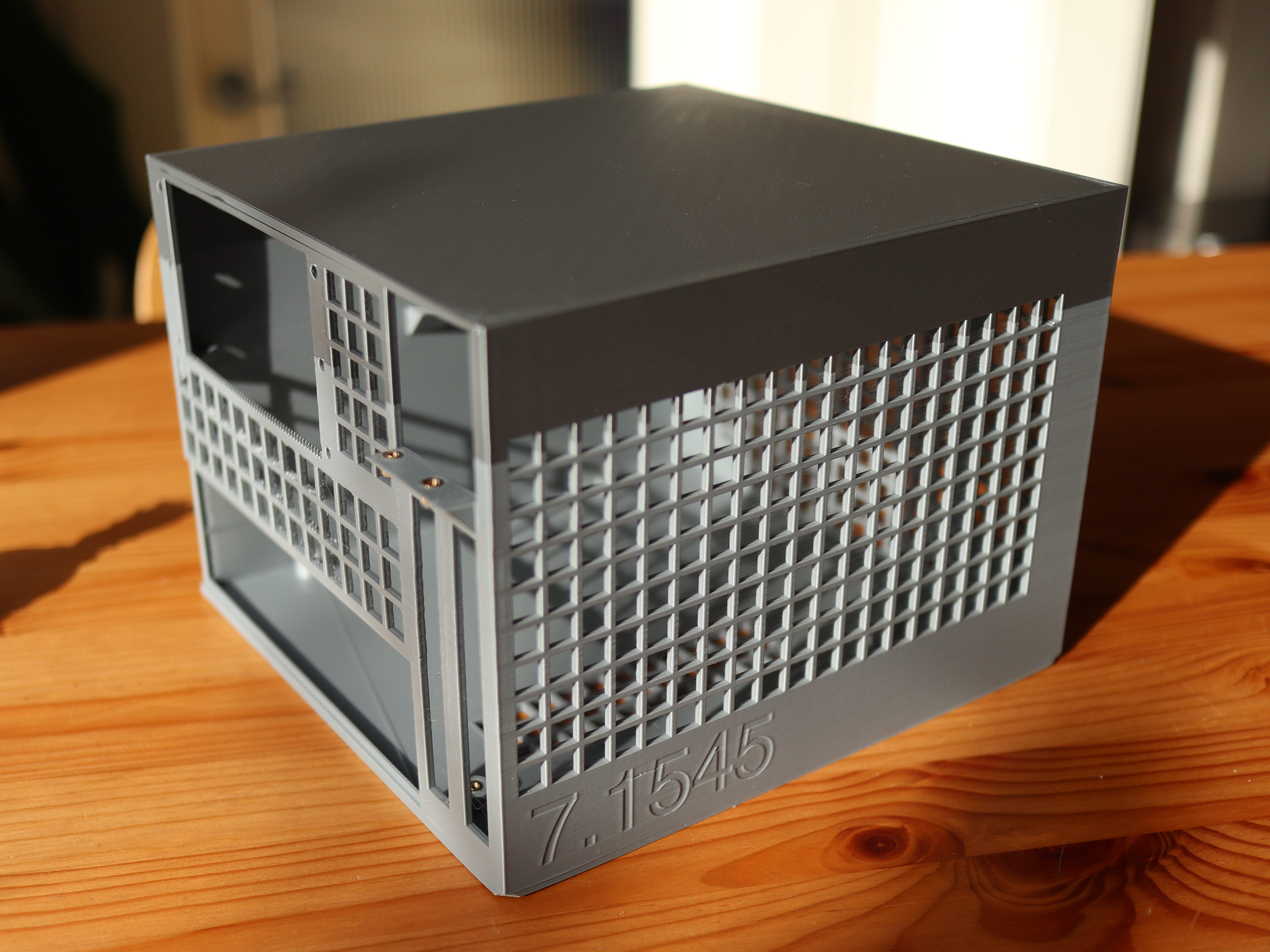

There are numerous popular 3D printable computer case designs available, including:

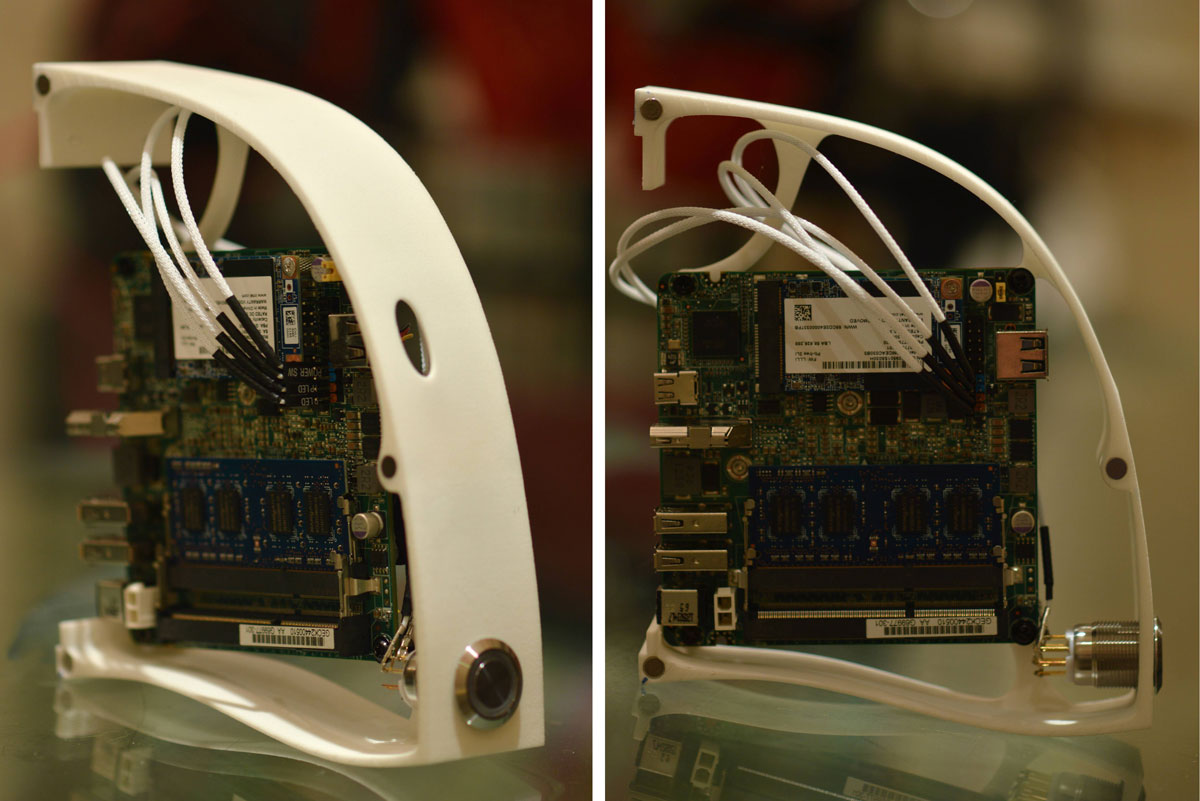

- Open Air Case: This design features an open-frame structure that allows for optimal airflow, reducing the risk of overheating. It is often used for gaming setups or high-performance systems.

- Slim Form Factor Case: These cases are compact and space-saving, making them ideal for small desk setups or for users who prefer a minimalist design.

- Modular Case: Modular cases allow for easy customization and expansion. They consist of separate modules that can be stacked or rearranged according to the user’s preference.

- Vertical Tower Case: This design is similar to traditional tower cases but with a vertical orientation. It provides a space-efficient solution while maintaining good airflow and accessibility to the components.

These are just a few examples, and the possibilities for 3D printable computer case designs are virtually endless. Users can explore various designs available online or even create their own unique cases using 3D modeling software.

Designing a 3D Printable Computer Case

Designing a 3D printable computer case requires careful consideration of both functionality and aesthetics. Here is an overview of the process and the tools and techniques used in the design.To begin designing a 3D printable computer case, it is essential to have a clear understanding of the requirements and specifications.

Consider factors such as the size of the computer components, cooling requirements, cable management, and any additional features desired.

Software Tools and Techniques

There are various software tools available for designing 3D printable objects, and some popular choices for designing computer cases include:

- Autodesk Fusion 360:This powerful software offers a wide range of features for 3D modeling and designing. It allows for parametric design, which enables easy modification and iteration of the design.

- SketchUp:SketchUp is known for its user-friendly interface and intuitive design tools. It is a great option for beginners or those looking for a simpler software.

- Blender:Blender is a versatile software that can be used for complex 3D modeling. It offers advanced features and is widely used in the 3D design community.

When designing a computer case, it is important to consider the following techniques:

- Measurements and Prototyping:Accurate measurements of computer components and dimensions are crucial for a proper fit. Creating prototypes using 3D printing can help test the design and make adjustments if necessary.

- Modularity:Designing the case in modular components allows for easier assembly and customization. It also facilitates upgrades or replacements of individual parts without the need to replace the entire case.

- Ventilation and Cooling:Proper airflow and cooling are essential for computer components. Incorporating ventilation holes, fans, or other cooling mechanisms in the design can help prevent overheating.

- Cable Management:Designing cable management features such as routing channels or tie-down points can help keep the cables organized and improve the overall aesthetics of the case.

Tips for Creating a Functional and Visually Appealing Design

Creating a functional and visually appealing 3D printable computer case requires attention to detail and careful planning. Here are some tips to consider:

- Simplicity:Keep the design simple and avoid unnecessary complexity. A clean and minimalist design can be both functional and visually appealing.

- Ergonomics:Consider ergonomics and user accessibility when designing the case. Easy access to ports, buttons, and components can enhance the user experience.

- Material Selection:Choose a suitable material for 3D printing that balances durability, aesthetics, and cost. Materials like ABS or PETG are commonly used for computer cases.

- Customizability:Design the case in a way that allows for customization, such as interchangeable panels or modular components. This enables users to personalize the appearance of their computer case.

- Consider Future Upgrades:Anticipate future upgrades and ensure the design accommodates them. This can include leaving room for additional storage drives, expansion slots, or compatibility with different motherboard sizes.

Designing a 3D printable computer case requires a combination of technical knowledge, creativity, and attention to detail. By following these tips and utilizing the appropriate software tools and techniques, you can create a functional and visually appealing computer case that meets your specific needs.

Materials for 3D Printing Computer Cases

When it comes to 3D printing computer cases, there are several materials commonly used in the process. Each material has its own set of advantages and disadvantages, and selecting the right material is crucial in achieving the desired properties for the computer case.One

of the most widely used materials for 3D printing computer cases is Acrylonitrile Butadiene Styrene (ABS). ABS is a strong and durable thermoplastic that can withstand higher temperatures. It is known for its impact resistance and is commonly used in industries such as automotive and electronics.

However, ABS can be prone to warping during the printing process and emits potentially harmful fumes, requiring proper ventilation.Another material option is Polylactic Acid (PLA), which is a biodegradable thermoplastic derived from renewable resources such as cornstarch or sugarcane. PLA is easier to print with compared to ABS and has a lower tendency to warp.

It also emits less odour and is considered more environmentally friendly. However, PLA is not as strong as ABS and has a lower heat resistance, which may limit its use in certain applications.Polyethylene Terephthalate Glycol (PETG) is another material commonly used for 3D printing computer cases.

PETG is known for its high strength, durability, and resistance to impact. It has good chemical resistance and can withstand higher temperatures compared to PLA. PETG also has low shrinkage and warping tendencies, making it an attractive option for printing larger computer case components.When

selecting the right material for a 3D printed computer case, it is important to consider the desired properties and requirements of the case. If strength and durability are a priority, ABS or PETG may be the better options. On the other hand, if environmental friendliness and ease of printing are important factors, PLA might be the preferred choice.In

conclusion, there are several materials commonly used for 3D printing computer cases, each with its own advantages and disadvantages. The choice of material depends on the desired properties, such as strength, heat resistance, and environmental impact. Understanding the characteristics of different materials can help in selecting the right material for a 3D printed computer case.

Customization Options for 3D Printable Computer Cases

D printable computer cases offer a wide range of customization options, allowing users to personalize their computer case design according to their specific needs and preferences. From cable management to fan placement, there are several features that can be customized to create a unique and functional computer case.

Cable Management

One of the key customization options for 3D printable computer cases is cable management. With traditional computer cases, cable management can often be a challenge, resulting in a cluttered and messy interior. However, with 3D printable cases, you can design cable management solutions that neatly organize and route cables, ensuring a clean and efficient setup.

This not only improves aesthetics but also promotes better airflow and cooling.

Fan Placement

Another customization option is fan placement. The cooling system is crucial for maintaining optimal performance and preventing overheating in a computer. With 3D printable cases, you have the flexibility to design and position fan mounts according to your specific cooling requirements.

This allows you to optimize airflow and cooling efficiency, ensuring that your components stay cool even during intensive tasks.

Component Compatibility

D printable computer cases also offer the advantage of component compatibility customization. Traditional computer cases often have fixed dimensions and layouts, limiting the compatibility of certain components. However, with 3D printing, you can design a case that perfectly fits your components, ensuring a snug and secure fit.

This customization option is particularly useful for users with unique hardware configurations or non-standard components.

Aesthetic Customization

Beyond the functional aspects, 3D printable computer cases also provide opportunities for aesthetic customization. You can design and incorporate personalized elements such as logos, patterns, or text onto the case, making it truly your own. Additionally, you can experiment with different colors and finishes, allowing you to create a computer case that matches your personal style and preferences.

Additional Features

In addition to the above customization options, 3D printable computer cases also allow for the integration of additional features. For example, you can design and 3D print brackets or mounts for accessories like custom liquid cooling systems, SSD holders, or RGB lighting setups.

These additional features enhance the functionality and aesthetics of your computer case, tailoring it to your specific needs.Overall, the customization options for 3D printable computer cases are virtually limitless. Whether it’s optimizing cable management, fan placement, component compatibility, or adding personalized aesthetic elements, 3D printing provides the flexibility to create a computer case that is truly unique and tailored to your requirements.

Assembly and Installation of a 3D Printable Computer Case

When it comes to assembling a 3D printable computer case, it is important to follow a systematic process to ensure a secure and proper fit. This involves understanding the necessary hardware and tools required for installation and implementing some tips to achieve optimal results.

Understanding the Hardware and Tools

Prior to starting the assembly process, it is essential to gather all the required hardware and tools. Here are some of the commonly needed items:

- Screws and fasteners: These are used to secure various components of the computer case together.

- Screwdriver: Make sure to have a suitable screwdriver that fits the screws used in your case.

- Zip ties: These are useful for cable management and keeping the interior of the case organized.

- Components: Ensure that you have all the necessary computer components such as the motherboard, power supply, graphics card, and storage devices.

The Assembly Process

Here is a step-by-step guide on how to assemble a 3D printable computer case:

- Prepare the case: Start by cleaning the 3D printed parts and removing any support structures if necessary. Check for any defects or imperfections that may affect the fit or functionality of the case.

- Mount the motherboard: Install the motherboard onto the designated mounting points inside the case. Make sure to align the screw holes on the motherboard with the corresponding holes on the case.

- Secure the power supply: Position the power supply unit in its designated location and use screws to secure it firmly in place.

- Install storage devices: Attach the storage devices such as hard drives or SSDs to their respective slots or brackets inside the case. Use screws or other fasteners to ensure they are securely mounted.

- Mount the graphics card: If you have a dedicated graphics card, insert it into the appropriate slot on the motherboard. Secure it using screws or any locking mechanisms provided.

- Connect cables: Carefully route and connect the necessary cables from the power supply, storage devices, and graphics card to their respective connectors on the motherboard. Use zip ties to manage and tidy up the cables for better airflow and aesthetics.

- Complete the assembly: Double-check all the connections, ensure everything is securely fastened, and there are no loose components. Close the case and secure it using the appropriate screws.

Tips for a Secure and Proper Fit

Here are some tips to ensure a secure and proper fit during the assembly process:

- Refer to the 3D printable computer case design specifications and instructions, if available. This will provide valuable guidance on the correct positioning and alignment of components.

- Take your time during the assembly process and be patient. Rushing can lead to mistakes or improper fitting.

- Double-check the compatibility of the components with the 3D printed case design. Ensure that the case has adequate space and mounting points for all the components you plan to install.

- Pay attention to cable management. Properly routing and securing cables not only improves airflow but also prevents any accidental disconnections or damage to the components.

- Regularly check and tighten the screws to maintain a secure fit over time.

Following these steps and tips will help you successfully assemble and install a 3D printable computer case, providing a secure and efficient housing for your computer components.

Maintenance and Upgrades for 3D Printable Computer Cases

As with any computer case, 3D printable computer cases require regular maintenance to ensure optimal performance and longevity. Additionally, upgrades may be necessary to keep up with the ever-evolving technology. In this section, we will discuss the maintenance requirements, share cleaning and troubleshooting tips, and provide guidance on upgrading components within a 3D printable computer case.

Maintenance Requirements, 3d printable computer case

To keep your 3D printable computer case in top condition, it is important to follow these maintenance requirements:

- Regularly clean the case: Dust and debris can accumulate inside the case, affecting airflow and potentially causing overheating. Use compressed air or a soft brush to remove dust from the case, paying special attention to the fans and vents.

- Check for loose connections: Over time, cables and components may become loose. Regularly inspect the connections and ensure everything is securely plugged in.

- Monitor temperatures: Keep an eye on the temperatures of your components to prevent overheating. Use software tools to monitor the CPU and GPU temperatures and take appropriate action if they exceed safe limits.

- Update firmware and drivers: Check for firmware and driver updates for your components, such as the motherboard and graphics card. Keeping them up to date can improve performance and fix any bugs or compatibility issues.

Cleaning and Troubleshooting Tips

Here are some tips for cleaning and troubleshooting common issues with your 3D printable computer case:

- Regularly clean the filters: If your case has dust filters, clean them regularly to prevent dust from entering the case. This will help maintain good airflow and prevent overheating.

- Check for cable management issues: Poor cable management can restrict airflow and lead to higher temperatures. Make sure cables are neatly routed and secured to avoid any airflow obstructions.

- Troubleshoot cooling system: If you notice your components running hot, check the cooling system. Ensure that the fans are working properly and that there is no blockage in the airflow path.

- Inspect for component damage: Periodically inspect your components for any signs of damage, such as bent pins or bulging capacitors. If you spot any issues, take appropriate action, such as replacing the damaged component.

Upgrading Components

One of the advantages of 3D printable computer cases is the ease of upgrading components. Here are some guidelines for upgrading components within a 3D printable computer case:

- Consider compatibility: Before upgrading any component, ensure that it is compatible with your motherboard and other existing components. Check the specifications and consult manufacturer guidelines if needed.

- Plan for adequate space: Take into account the physical dimensions of the new component and ensure that it will fit comfortably within your 3D printable computer case. Consider any necessary modifications to accommodate the new component.

- Follow proper installation procedures: When installing a new component, follow the manufacturer’s instructions carefully. Improper installation can lead to damage or malfunction.

- Upgrade gradually: If you plan to upgrade multiple components, it is generally advisable to do so gradually. This allows you to test each new component and ensure stability before proceeding to the next upgrade.

Future Trends in 3D Printable Computer Cases

D printing technology has revolutionized various industries, and the world of computer cases is no exception. As the technology continues to advance, we can expect to see exciting emerging trends in 3D printable computer case design. These trends will not only enhance the aesthetics of computer cases but also improve their functionality and customization options.

Integration of Advanced Cooling Systems

One of the key areas where we can expect to see advancements in 3D printable computer case design is in the integration of advanced cooling systems. As powerful computer hardware generates more heat, efficient cooling becomes crucial to maintain optimal performance and prevent overheating.

In the future, 3D printable computer cases may incorporate intricate cooling channels and innovative cooling solutions, such as liquid cooling, to ensure efficient heat dissipation.

Modular Designs for Easy Upgrades

Modularity has become a popular trend in computer hardware, allowing users to easily upgrade or replace components. In the future, we can expect 3D printable computer cases to embrace modular designs, making it easier for users to customize and upgrade their systems.

With modular computer cases, users can easily add or remove components, accommodating new hardware advancements without the need to replace the entire case.

Integration of Smart Features

As the Internet of Things (IoT) continues to expand, we can anticipate the integration of smart features in 3D printable computer cases. These smart features may include built-in sensors, RGB lighting controls, and connectivity options to enhance the user experience.

Imagine a computer case that automatically adjusts its lighting based on ambient light conditions or a case that can be remotely monitored and controlled through a smartphone app. The possibilities are endless, and 3D printing technology makes it feasible to incorporate such smart features seamlessly.

Exploration of New Materials

D printing allows for the use of a wide range of materials, and we can expect future trends in 3D printable computer case design to explore new materials. While plastic remains a popular choice for 3D printing computer cases, advancements in materials science may lead to the adoption of stronger and more durable materials, such as carbon fiber composites or metal alloys.

These materials could offer enhanced structural integrity and improved protection for computer components.

Customization Beyond Aesthetics

Customization has always been a significant advantage of 3D printable computer cases, allowing users to create unique designs that suit their preferences. In the future, we can expect customization options to go beyond aesthetics. With advancements in 3D printing technology, users may be able to customize the internal layout of their computer cases to optimize airflow, cable management, and component placement.

This level of customization can lead to improved performance and overall system efficiency.

Challenges and Benefits

While the future of 3D printable computer cases looks promising, there are both benefits and challenges to consider. On the positive side, 3D printing allows for rapid prototyping and customization, reducing the time and cost involved in traditional manufacturing processes.

Additionally, the ability to easily iterate designs and incorporate user feedback can result in highly optimized computer cases.However, challenges such as print quality, material limitations, and scalability need to be addressed for widespread adoption of 3D printable computer cases. Achieving consistent print quality, especially for intricate designs, can be challenging.

Furthermore, the availability of high-quality materials at an affordable cost can limit the design possibilities. Overcoming these challenges will be crucial for the future success of 3D printable computer cases.In conclusion, the future of 3D printable computer cases holds exciting possibilities.

If you’re looking for a 100 chart printable free, you’re in luck! You can find a great resource at this website . This printable chart is a handy tool for teaching and practicing numbers. It’s perfect for young learners or anyone who wants to brush up on their counting skills.

With this printable, you can easily visualize numbers up to 100 and use it for a variety of math activities. Whether you’re a teacher, parent, or student, this 100 chart printable free is a valuable resource to have.

With advancements in cooling systems, modular designs, smart features, new materials, and enhanced customization options, computer cases will not only protect hardware but also become a reflection of personal style and functionality. However, addressing challenges and ensuring widespread adoption will be essential to harness the full potential of 3D printable computer cases.

Last Point: 3d Printable Computer Case

In conclusion, 3D printable computer cases are revolutionizing the way we build and personalize our PCs. With their versatility and endless design options, these cases provide a stylish and functional solution for tech enthusiasts. Embrace the future of computer hardware with 3D printing and take your PC builds to the next level.

FAQ Section

What are the benefits of using a 3D printable computer case?

Using a 3D printable computer case allows for complete customization, ensuring a perfect fit for your components. It also offers the opportunity to create unique designs and showcase your personal style.

Which materials are commonly used for 3D printing computer cases?

Common materials for 3D printing computer cases include PLA, ABS, and PETG. Each material has its own advantages, such as PLA being easy to print with and PETG offering better durability.

How do I assemble a 3D printable computer case?

Assembling a 3D printable computer case follows a similar process to traditional cases. Start by attaching the motherboard, followed by installing other components such as the power supply, GPU, and storage devices.

What are the maintenance requirements for 3D printable computer cases?

Regular cleaning and dusting are important for maintaining a 3D printable computer case. Additionally, it’s essential to ensure proper ventilation and airflow to prevent overheating.

How can I upgrade components within a 3D printable computer case?

Upgrading components in a 3D printable computer case is similar to traditional cases. Simply remove the old component and replace it with the new one, ensuring compatibility and proper connections.